Why Brass Inserts Are the Best Choice for Plastic, Wood & Metal Assemblies (Complete Supplier Guide 2025)

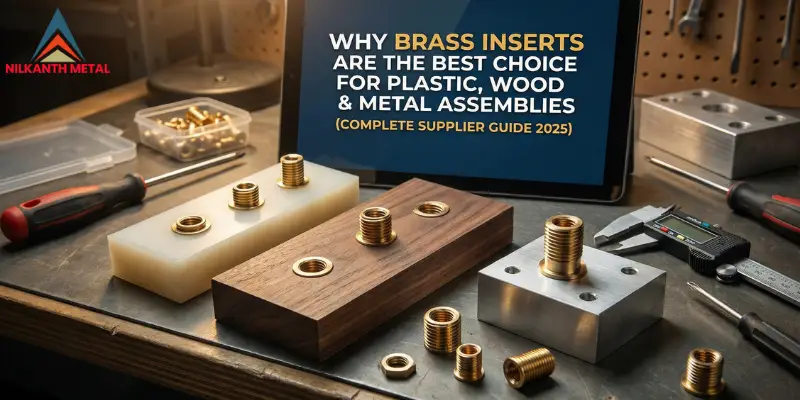

For manufacturers and crafters, creating strong, secure joints among a variety of materials (including plastic, wood, and metal) is vital. A very versatile and effective way to make these types of connections is with the use of brass Inserts. Brass are small threaded fasteners that are inserted into softer materials so that the threads can be used to attach screws and bolts to the material. As we approach the year 2025, the continued advancement of sustainable manufacturing processes and precision engineering will provide further growth opportunities for brass. This article provides all of the reasons are the ideal solution for creating assembly joints in many different types of material, along with helpful hints and tips for sourcing your brass insert materials via a comprehensive supplier reference.

What are brass and how are they used? Brass are also referred to as nesters or threaded inserts; they are cylindrical brass alloy pieces that contain internal threads (threads are where the screws attach) and are typically made from a combination of copper and zinc. Brass are permanently fused to the host material and provide more secure attachment points than regular screws, which strip easily and become loose with repeated use. When brass are used properly, they evenly distribute the stress on the brass insert and provide protection against damage to the material.Brass's natural properties result in their resistance to corrosion, which makes them ideal for environments where moisture or chemicals may be present. As we move into 2025, we continue to see the increase in use of eco-friendly brass made from recycled materials, which is consistent with global sustainability goals.

Key Benefits of Using Brass Inserts

There are numerous advantages of using brass inserts as opposed to plastic or steel inserts. The following is a summary of why you should consider using brass:

- Durability and Strength: Brass is stronger than many plastics and softer than steel. Brass has the ability to conform to the material it is being inserted into without causing damage. Because of this, assemblies using brass are able to withstand high torque and repeated use.

- Corrosion Resistant: Brass does not rust like iron-based inserts so they are well suited for outdoor or humid applications.

- Thermal Conductivity: Brass conducts heat better than most materials, making it an excellent choice in electronic components or engines.

- Ease of Installation: Brass can be installed using ultrasonic welding, heat staking, or press fitting, and require very few tools.

- Cost Effective: Cost Effective: Brass are inexpensive and reusable, meaning they will save you money long-term due to reduced maintenance costs.

- Versatile: Brass can be used in conjunction with a variety of materials including thermoplastics and hardwoods.

Ultimately, when compared to other choices brass provide higher durability and better reliability, especially in demanding environments such as automotive and electronics.

Plastic Assemblies with Brass

Brass are ideal for enhancing the weakest parts of plastic assemblies because plastic assemblies can be found in a huge range of products, from consumer electronics to automotive parts. Thread stripping in various plastics like polycarbonate, nylon, and ABS is common. Brass provide a strong, threaded connection to give more support to the respective material.

Brass in plastic enclosures, for example, provide a secure way to mount connection points and circuit boards. Brass are installed by ultrasonic insertion, which causes enough vibration to melt the surrounding plastic into a solid bond. This method is quick and does not require the use of any kind of adhesive. In addition to all the new materials that are going to be printed in 3D in 2025, brass are already capable of being manufactured with more complicated geometries to increase durability.

Some benefits of brass include an increased load capacity and an increased resistance to vibration, which makes them very well suited to high-volume manufacturing applications. Brass are ideal for applications ranging from toys to appliances to medical devices, as they increase the longevity of the product and reduce the number of product failures due to material degradation.

Brass Inserts for Wood Assemblies

The unique properties of wood, including porosity and grain pattern, allow brass inserts to add incredible value to wood furniture, cabinetry, and woodworking projects. Brass are a great alternative to traditional wood screws, which will frequently become loose due to the natural movement of the wood as it expands and contracts. By providing a threaded connection that creates a solid, lasting connection, brass provide far greater dependability than wood screws.

Drilling a pilot hole and threading the insert with a tool or using self-tapping types are two common ways to install an insert, although the latter option is generally easier and quicker. Brass also provides corrosion resistance for outdoor or marine furniture applications by resisting the harmful effects of weather. When manufactured as inserts for hardware application in building wooden boats, the hardware will be held in place by the insert without causing any damage to the wood itself.

As we approach the year 2025, more and more woodworkers who focus on sustainability are now able to incorporate brass as part of a brass project into their sustainable timber projects. Because they can create a product that is able to be disassembled and reused, they will continue to grow in popularity for custom furniture making as well. Brass can create a soft metallic accent that complements the natural beauty of wood.

While the use of brass in the manufacture of metal assemblies may seem excessive, there are advantages to using brass for inserts in softer metals such as aluminium or thin steel. In aerospace and automotive industries where reducing the weight of products is critical to performance, brass create strong joints while providing an additional level of structural integrity to lightweight metals without adding weight or bulk.

By tapping or press-fitting brass, they provide threads that are designed to withstand heavy loads and prevent thread wear. For example, many manufacturers are now incorporating brass into the construction of aluminium frames used to support electronic devices to prevent thread wear and provide consistent and reliable fastening, as well as to reduce the effects of heat on electronic devices. In the year 2025, as electric vehicles continue to trend upwards, brass will be used extensively in the manufacture of battery housings and chassis assemblies due to their resistance to vibrations and thermal properties.

Complete Guide for Brass Inserts Suppliers 2025

With online suppliers, sourcing brass inserts from suppliers around the world has never been easier in 2025. This guide will walk you through how to source the best brass suppliers.

- Brass Suppliers: Look for suppliers with established reputations as well as some Indian suppliers You can also locate international suppliers by searching on Alibaba and Thomas Net for bulk brass suppliers.

- Things to Consider: Be sure you find brass suppliers who produce RoHS-compliant, recycled brass. Verifying certification to ISO 9001 will provide assurance of quality. Expect use of artificial intelligence to create custom designs for brass in 2025.

- Price Range and Trends: Pricing for each brass will range from $1.00 per insert (depending on the size and quantity purchased) and a trend of environmentally friendly sourcing and smart packaging for reduced waste will continue in 2025.

- How to Select Brass Suppliers: Select suppliers based on compatibility of materials, the thread type of the insert (e.g., UNC or metric), and the installation method. Request samples from potential suppliers and read supplier reviews on sites like Trust pilot.

- Sustainability Focus: Select suppliers who have green initiatives, such as using recycled brass, in order to help reduce your company's impact on the environment.

When purchasing, verify lead times from suppliers; if they offer express shipping, that option is preferable; and, verify that brass will function with your tools and/or assembly methods.

Brass provide a highly reliable way to connect and combine plastic, wood & Metal manufacturing products. They provide an extended lifespan for both hobbyist & manufacture uses due to their high levels of strength and durability, and also provide an inexpensive & eco-friendly alternative for producing a variety of manufacturing products into the future. Brass are available through a well-established supplier, who will provide the highest quality of brass insert to meet your formatting requirement. Use brass to achieve a better and more durable assembly for future projects.

Recent Post

september, 12 2025

Brass Fasteners Manufacturer - Quality, Durability, and Precision with Nilkanth Metal

August, 20 2025

UHF Plug Connector: A Comprehensive Guide

April, 28 2025

Your Trusted Source for High-Quality Brass Air Valves

February, 14 2025

Versatile Brass and Steel Screws Customized for Industrial Sectors

July, 19 2024

What is Core Vents?